Space Tank Residency 2022-2023

Creators Fund

In 2022 I received a Creators Fund grant from Creative Victoria. The Creators Fund, unlike most other grants, does not require full concept realisation, presentation or audience engagement. Instead, the program encourages participants to concentrate on initial exploratory stages and research of new ideas; including testing, deep research, development or experimentation. This was a perfect opportunity for me for so many reasons, and also accessible for me in a way many other opportunities are not.

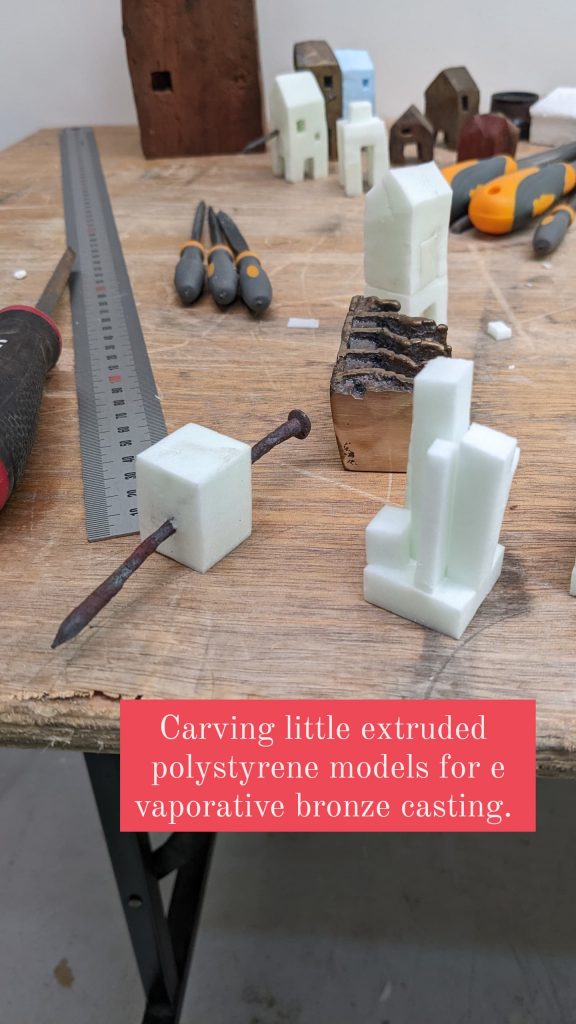

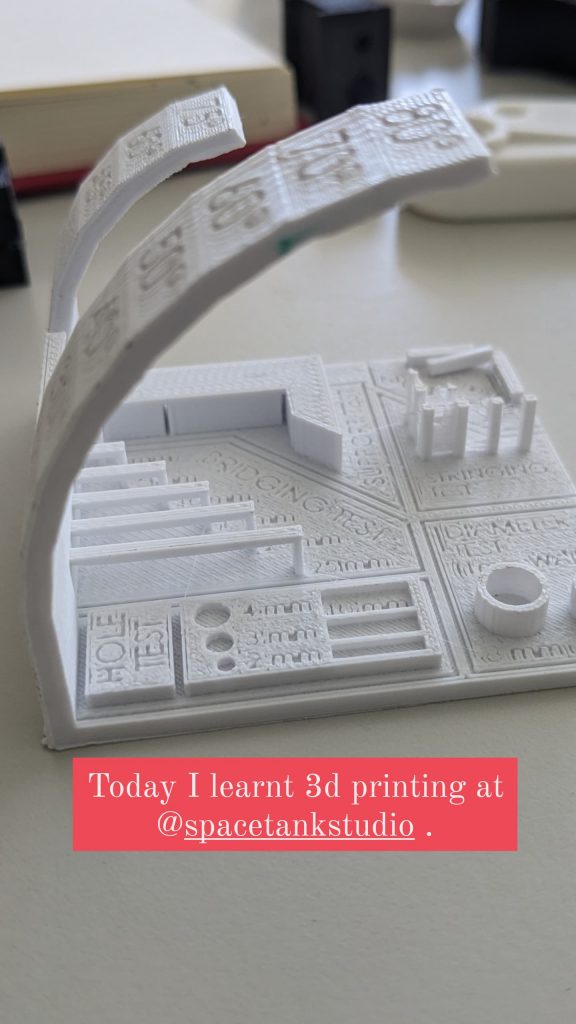

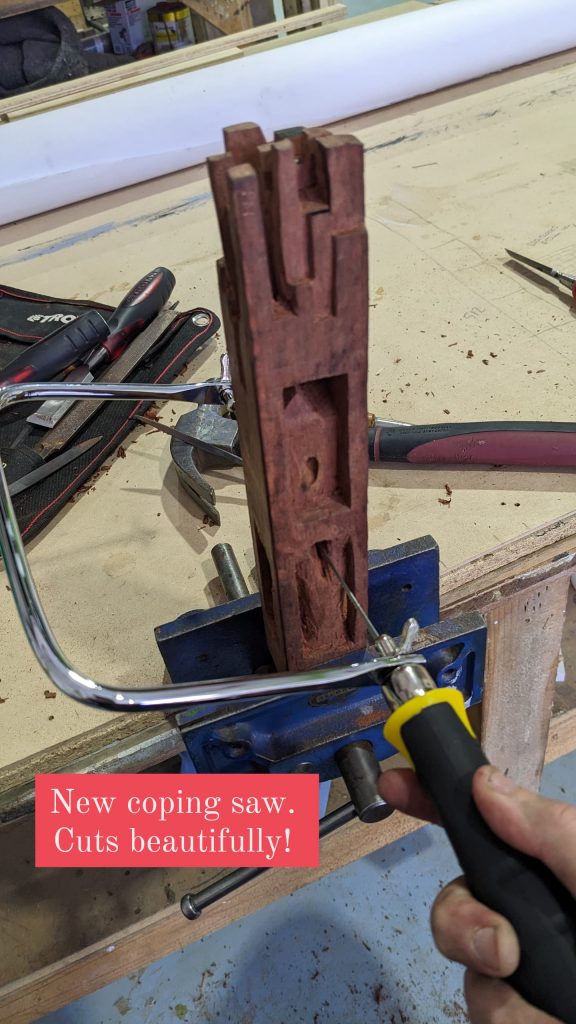

I proposed that I wanted to focus on expanding my sculptural practice and experiment with bronze casting. The fund supported me to hire a studio at Space Tank Studio, an incredible maker space in Coburg North, and receive mentoring in wide variety of new fabrication techniques including welding, 3d printing, woodwork and metal casting. I especially wanted to experiment with mixing materials I already use – red gum, found objects, metal, concrete and cutlery – with the evaporative bronze casting process.

The works here are the outcomes of my main focus during the grant – evaporative bronze casting. They are a mixture of experiments and close to final pieces.

The impact of the Creators Fund, without overstating the fact, has been life changing. With this support, I was able to spend dedicated time in a dedicated space to focus on my creative practice. I’ve never before worked in a studio that was not my garage. So this in itself was a new and intensely rewarding experience. The grant’s focus on experimentation, research and play allowed me to think and imagine expansively, to move in different directions, to not be restricted or concerned over outcomes and trajectories. Being supported to simply spend my time creating and experimenting was exhilarating and liberating. I’m proud of the work I developed. And also buoyed by the breadth of ideas I came up with during this time, that I now have ahead of me to explore.

First Casting Day

Aim

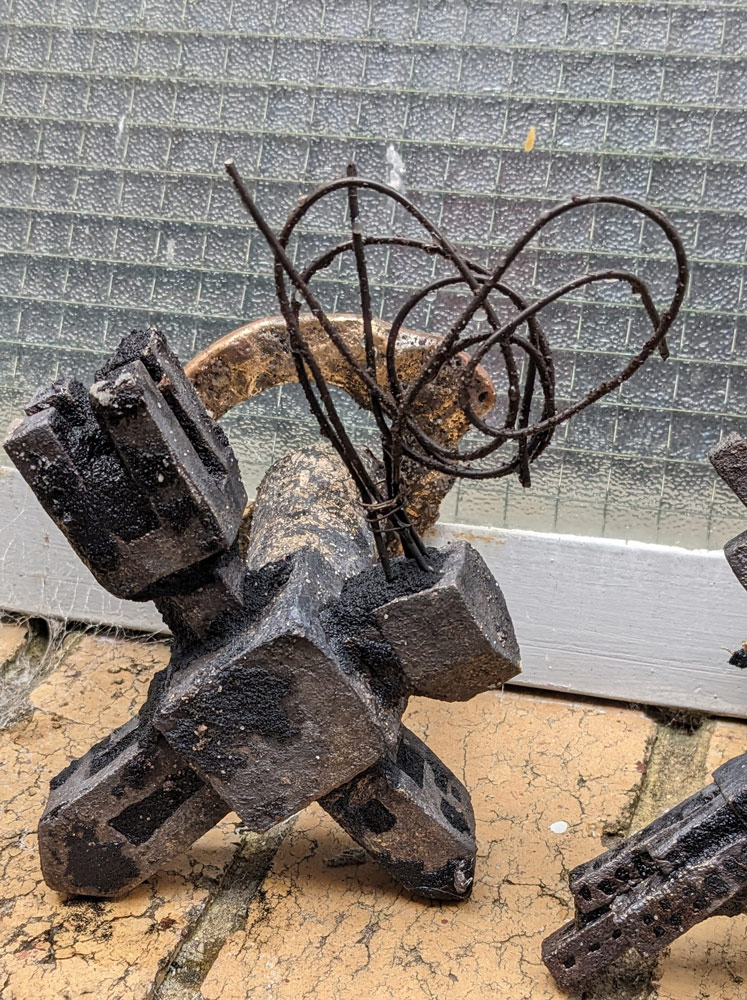

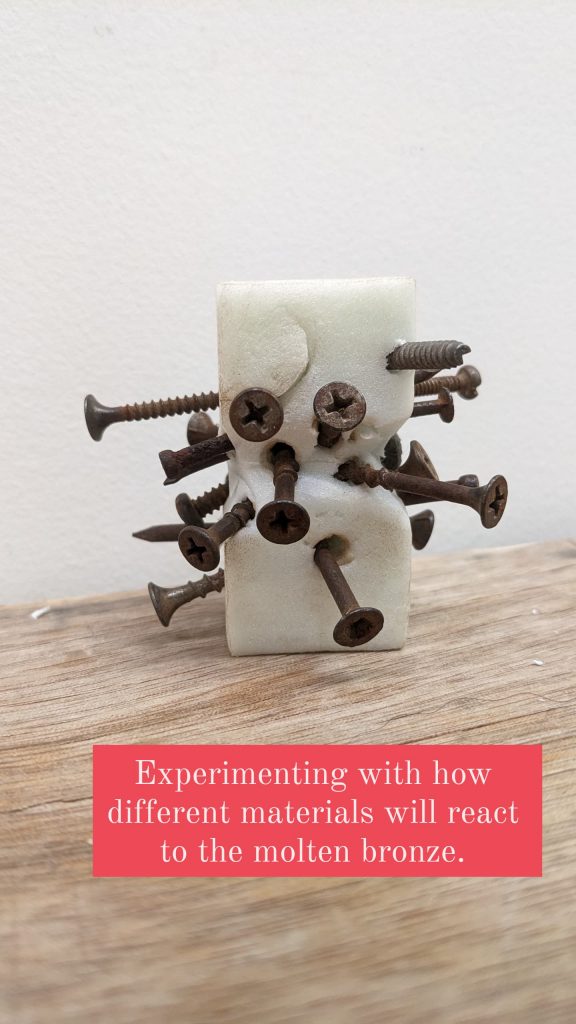

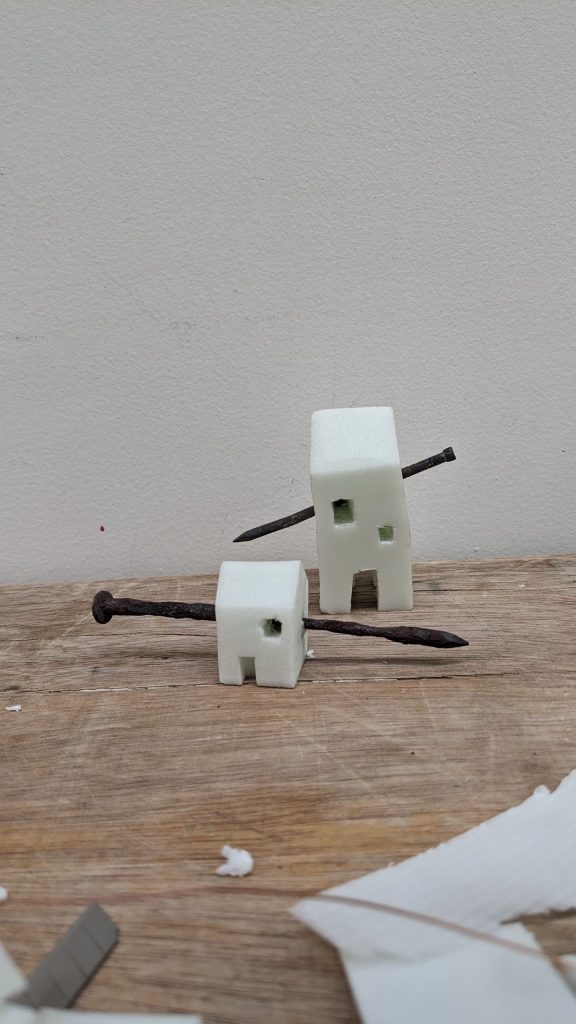

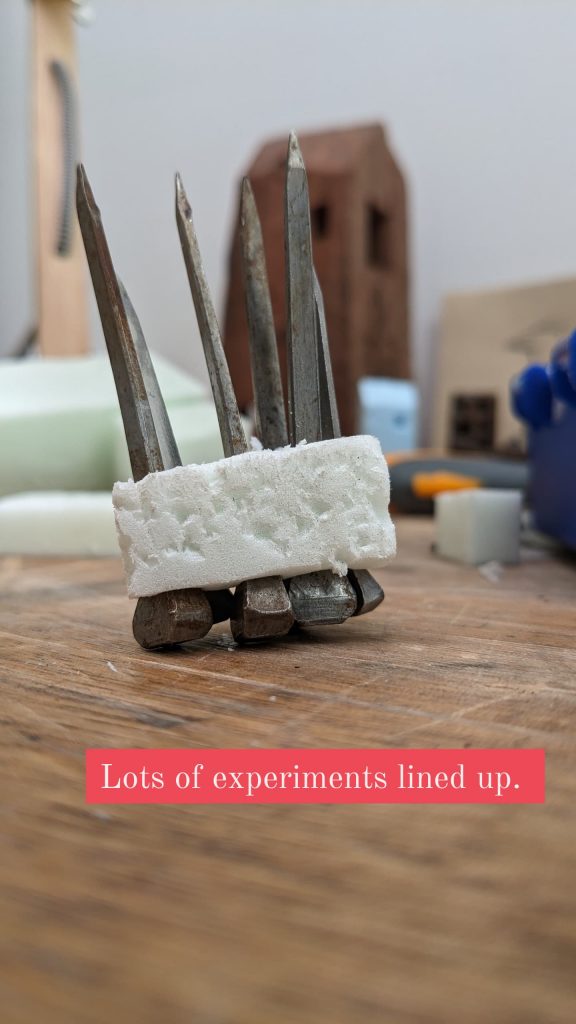

The aim for my first day of casting was to experiment with how different metals would react to the molten bronze. I made models with a variety of metal additions, including copper tubing, old rusty nails, copper wire, etc

I had no idea at this point how any of it would work. Would they explode? Had I unwittingly created IEDs? Would the different metals melt or fuse? These were some of the unknowns that I was eager to explore.

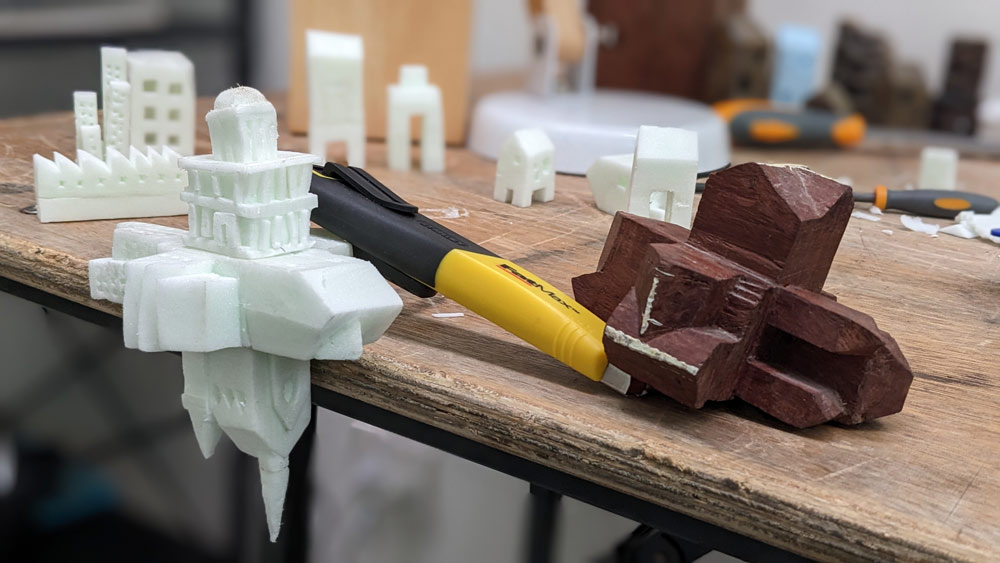

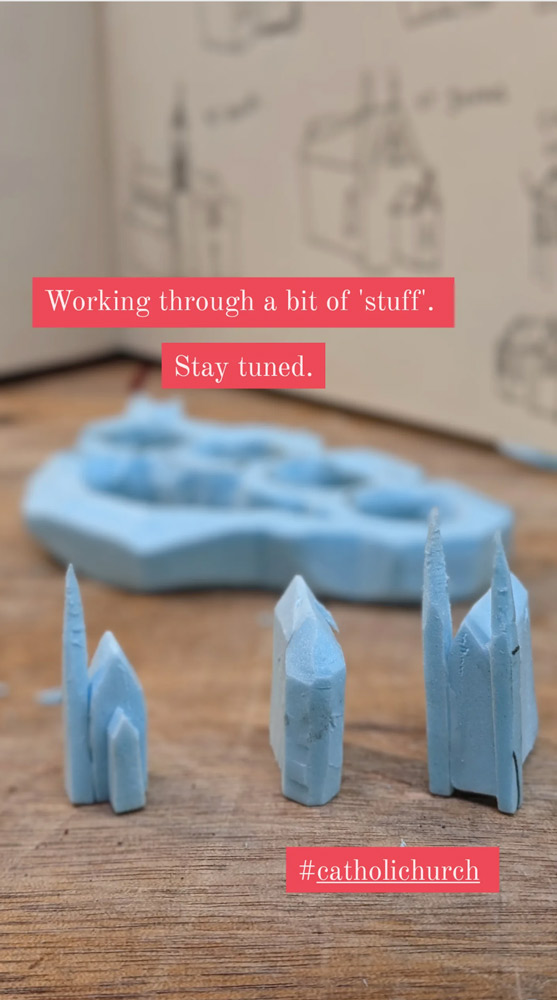

Another aspect of the process that I was interested to discover was how much detail could I achieve and what were the limits of long, thin elements like church steeples and office buildings.

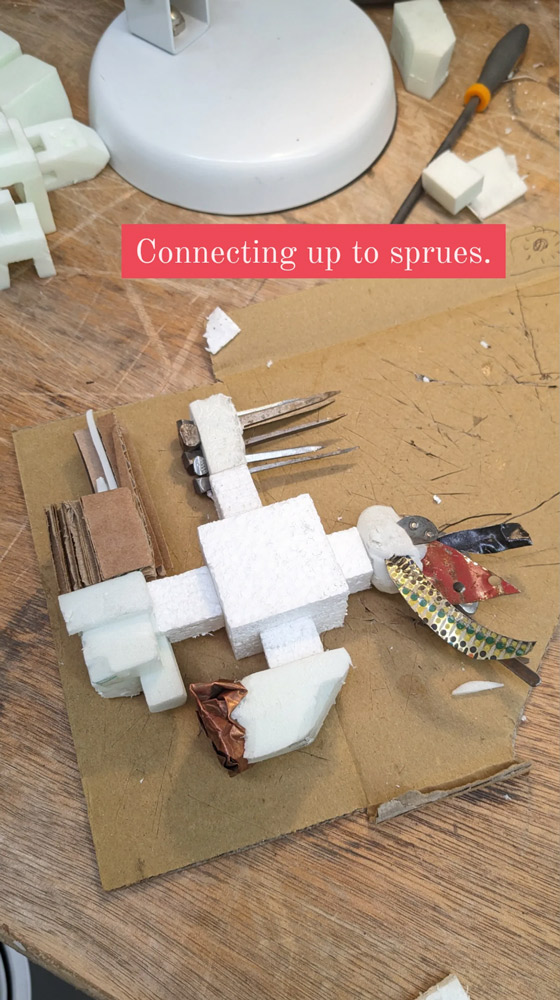

Most of the pieces for this first cast were for experimental purposes. But there was one piece that I hoped would become a finished work. Based on an earlier prototype I had carved in red gum, this piece has six buildings protruding from a central point. My red gum version had failed when one side cracked off during the carving process. Bronze seemed like a better option.

The process.

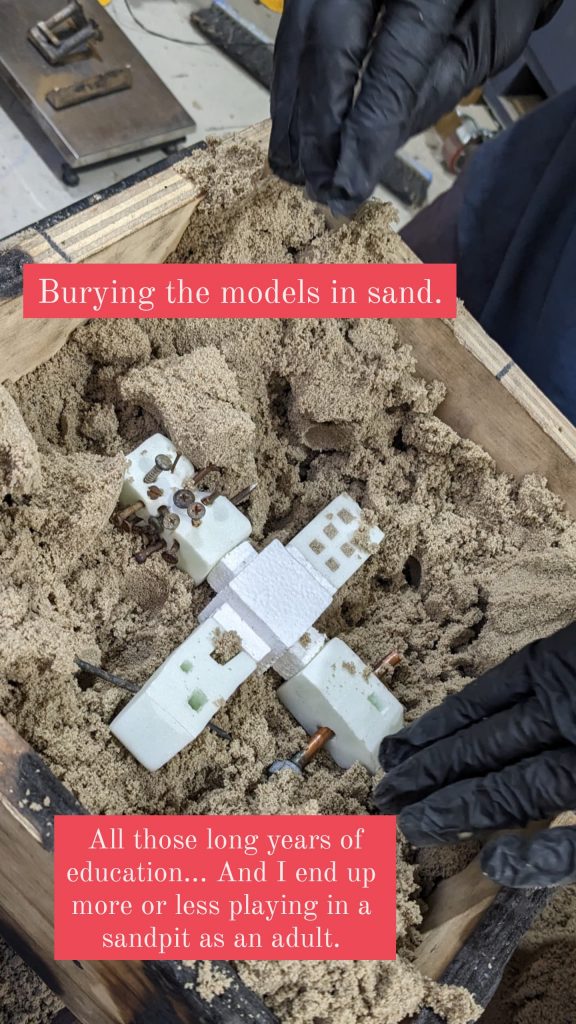

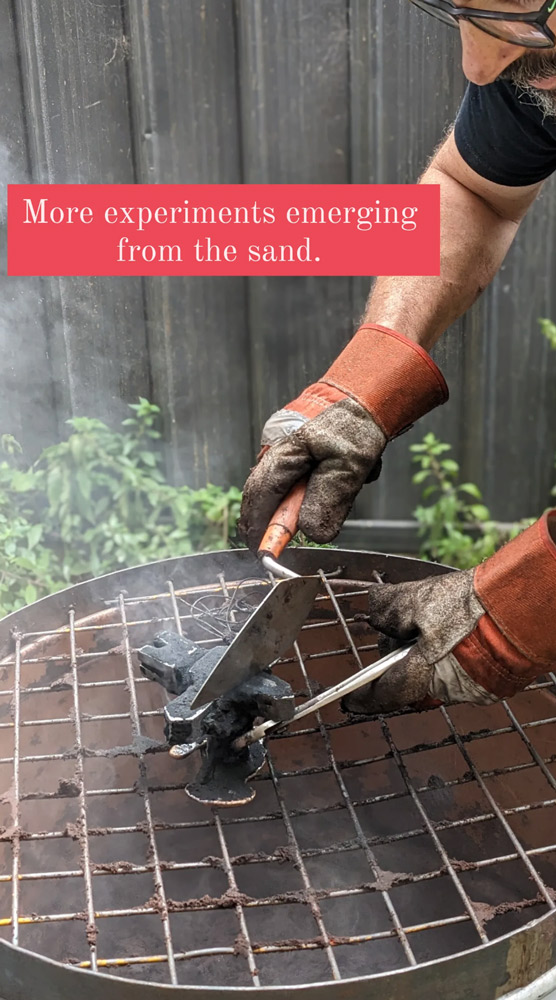

The process of evaporative bronze casting begins with making the foam molds – a positive, one-off render of your final piece. This piece is then attached to sprues so multiple pieces can be fed from one pour. The models are then packed into boxes with a specific type of sand which holds it’s shape well. When the bronze is poured in, the polystyrene evaporates and the bronze fills the resulting cavity.

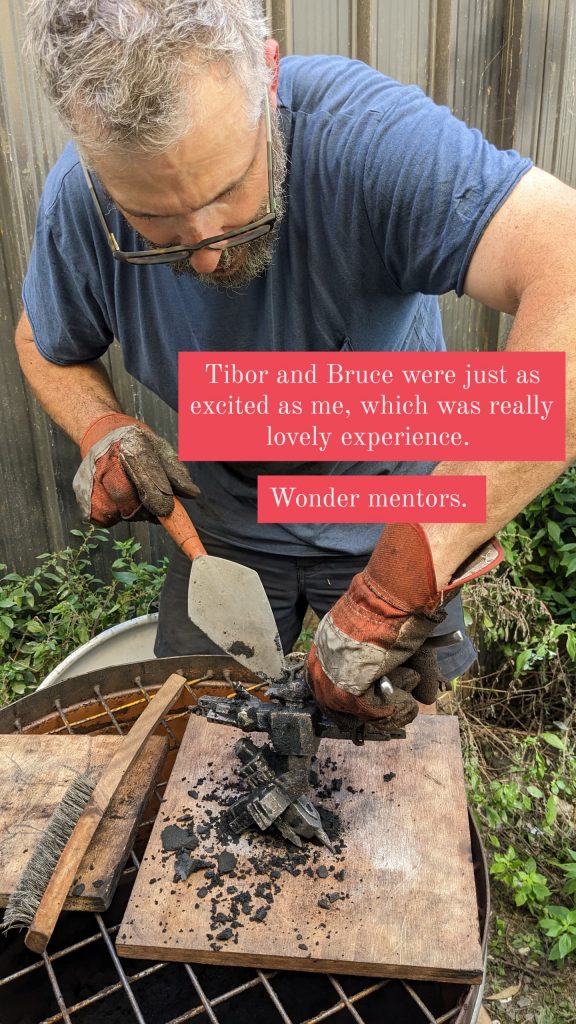

Having done evaporative bronze casting once before in a short course, the process was not a total mystery to me. But with one-to-one mentoring I had the chance to learn more about the casting method with its many nuances, sensitivities and intricacies.

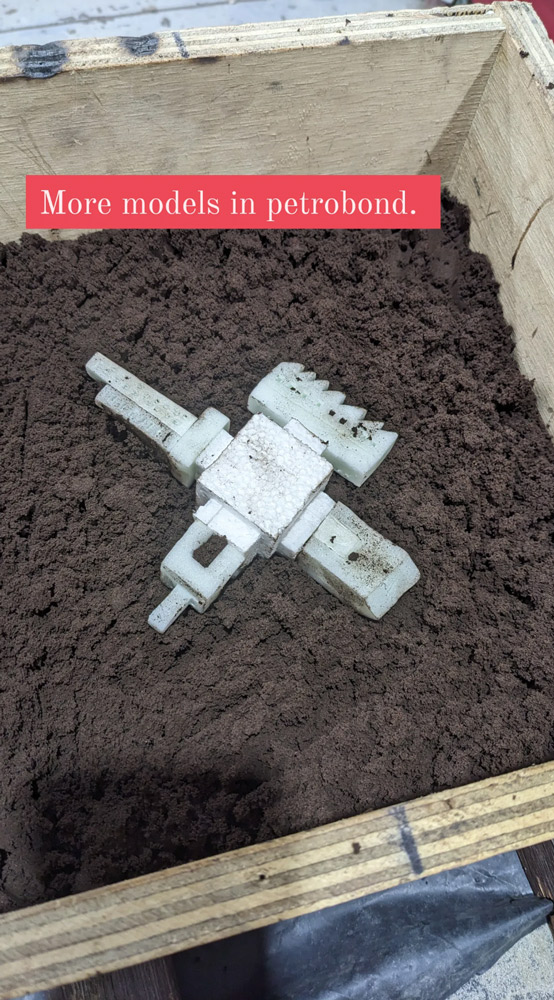

For this first round of casting I used two types of sand; greensand ( a water based mixture of premium foundry sand and bentonite, and petrobond (an oil based mixture of foundry sand, petrobond oil and petrobond powder). I was curious to see how the different casting sands would work.

Outcome

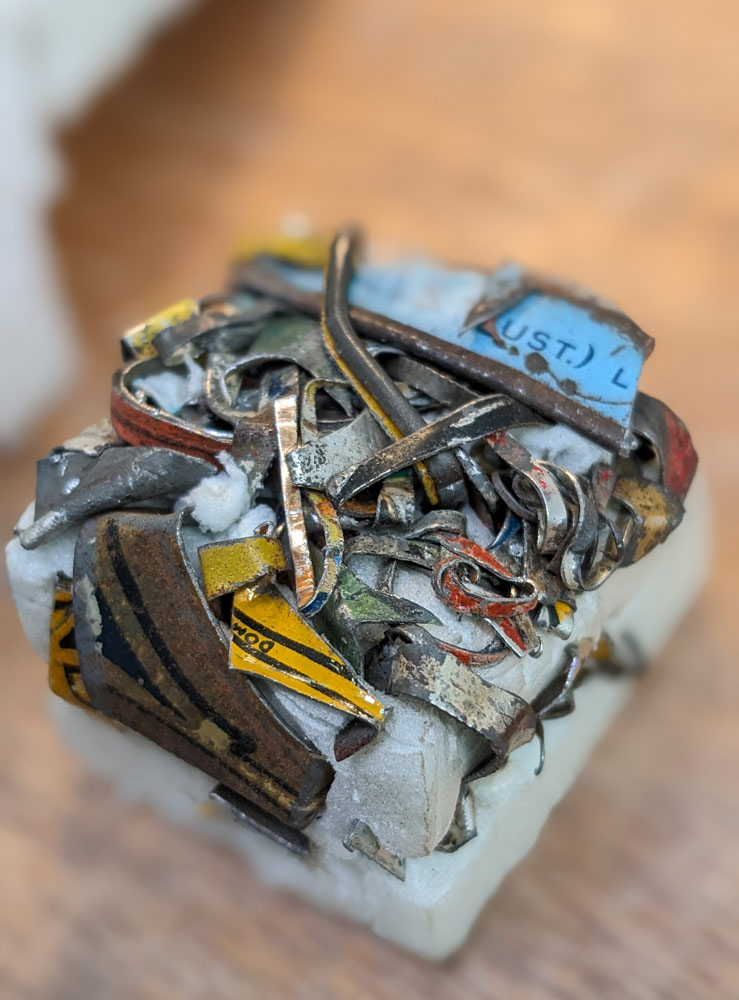

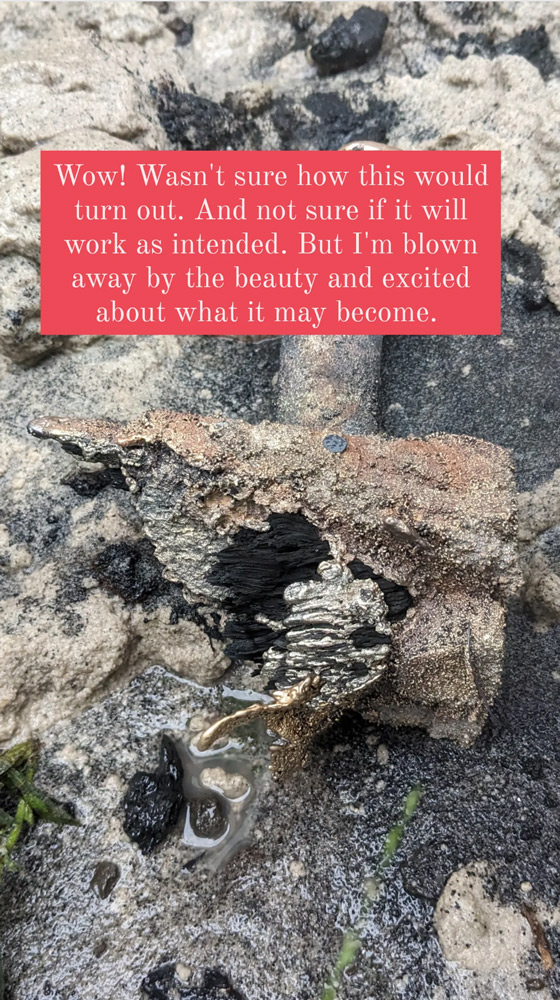

I was really pleased with the results. No explosions! I discovered that metal additions fuse, but do not melt. Pros and cons in this discovery. Now I can plan more experiments accordingly.

The finish comes out very differently between the two types of sand. The pieces that were in the green sand came out with quite a rough texture. Those in the petrabond had a smoother finish and more refined detail.

I learned to use an angle grinder for the first time (which has been on the to-do list for decades) in order to cut the sculptures off the sprues. It was so easy, I wish I hadn’t been so intimidated to try earlier in my life. This is a benefit of being at Space Tank – there are lots of highly and multi skilled people around who can teach you things as you need to know them.

The ‘hero’ piece for this pour came out beautifully. The Greensand Foundry crew and I were ecstatic when we saw the little steeples of the cathedral emerge from the sand and to discover that so much detail had been preserved.

Second Casting Day

Aim.

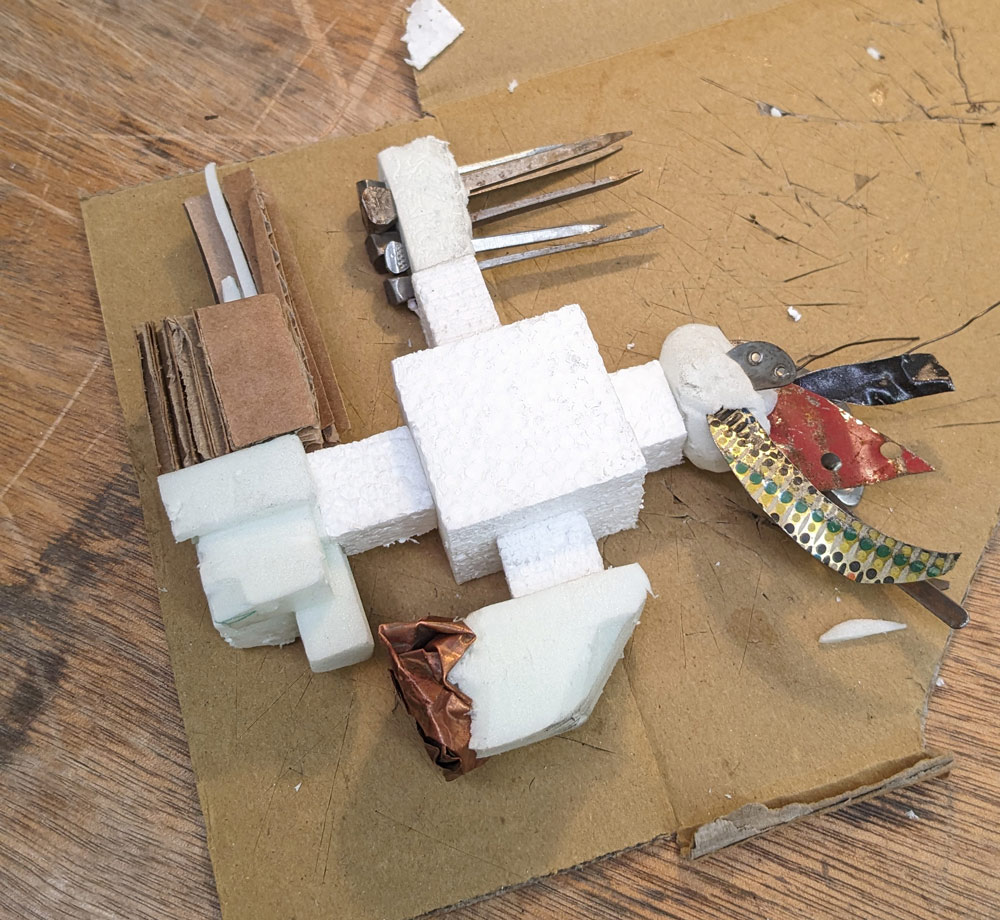

Having tested whether strong metals like copper piping and nails would melt or fuse with the casting process, I wanted to see what would happen with thinner metals. I created some tests using tin, copper foil, mechano, hair clips, and very thin military trip wire.

I also wanted to test pouring bronze onto red gum. What would happen to the wood? Would it create a perfect fuse? Would it burn? Would it explode?

Results

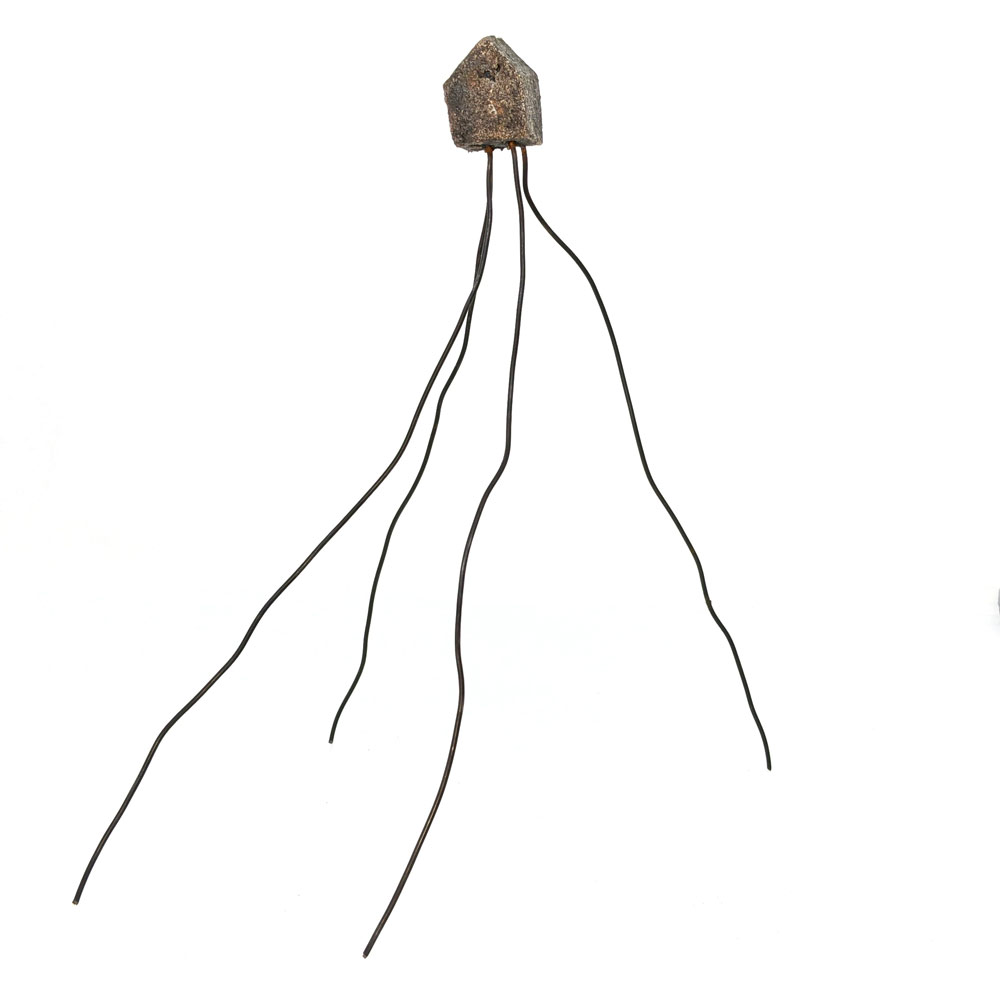

Another round of interesting experiments. The tin fused but didn’t melt at all as I was hoping. It also lost all its colour, which made it an unappealing prospect for future use. Amazingly, the trip wire held up. It suffers from more easily from metal fatigue near the point of junction after the process. But providing I don’t manipulate it too much, it opens up possibilities of creating bronze sculptures with platforms or towers made with wire – building on previous concepts in concrete.

As for pouring molten bronze straight on to red gum timber. There were a lot of flames! The wood ignited and burned for some time. When we released the timber and bronze, we doused it with water to halt the burning. There were some beautiful results. I was hoping to find a method to create bronze that could slot in exactly into the jagged edges of old timber. This didn’t entirely work because of the ignition. But the charred bits that were created were beautiful and delicate like the gills of a mushroom. Unfortunately, with a few rounds of placing the bronze and timber together, the most delicate of these were destroyed. I’d love to explore this idea further and see if there is a way I can preserve the charred edges.

Third Casting Day

Aim

The third casting day was nerve wracking! This was the first time I really had some skin in the game. On the previous pours, most of the pieces were experiments and whatever happened would be interesting and informative. This third and final casting day was really the culmination of the learnings from the previous pours.

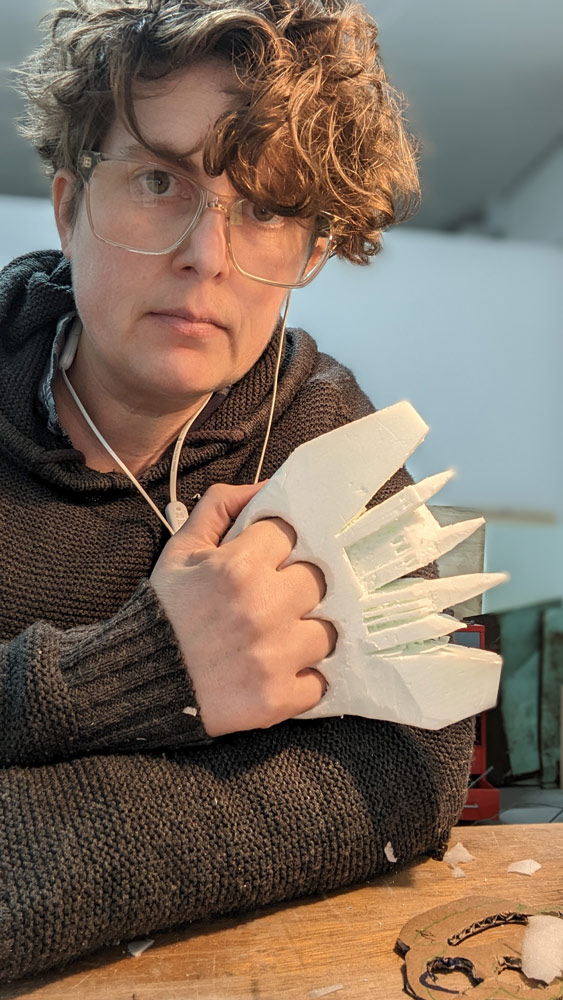

I worked on several pieces – two sets of brass knuckles, four uteruses and a maze house. As you do. Each piece took many, many hours to carve and prepare in foam. The brass knuckles with churches and cathedrals took over 10 hours to carve. Evaporative bronze casting is a one time deal. That’s a lot of work down the drain if the pour doesn’t work! So for the first time it really felt like more was at stake. I hoped things would turn out as planned, but also cautioned myself that I’m still learning and experimenting and that any results would still be educational.

Challenges

Energy levels were a major challenge for me. With MS, I usually only work for couple of hours at any stretch. The nature of casting days means that it’s not really possible to do the process in smaller steps. I really struggled, as my body got tired from packing the sand, to keep up my concentration and commitment. I knew that all the long hours of preparation was only as good as the success of the packing of the mould, but it was still difficult to wrangle my wobbly hands and fatiguing brain. I think if I continue in this medium, I will have to devise some workarounds and accomodations regarding this challenge.

I knew I was tempting fate with the thinness of the fallopian tubes on the uteruses. They were hard to carve in foam. I made them thicker than they needed to be in order to try to accomodate a good flow of bronze. All of them failed in one way or another but that was not entirely unexpected, and I think visually and conceptually they still achieve the intended goal. Next time I make thin channels like this I’ll have to be more careful in how I approach them.

Results.

Hooray! Everything turned our more or less how I hoped! So exciting!

My fatigue really let me down with figuring out where to put the venting ducts. In some cases, the ducts hit the models in less than ideal places which required more than necessary clean-up. Some models could have benefited from more coordinated fine motor skills to ensure I capture all the details. And for some unknown reason, the maze house produces a massive flame which interrupted the pour and resulted in a house with no roof. But overall I was very happy with this pour.

Now begins the process of learning about finishing the pieces with cutting and polishing and experimenting with treatments for different patinas.

Conceptually, these pieces deal with some very hefty themes. It will take some time to put their meanings and intentions into words.

Videos

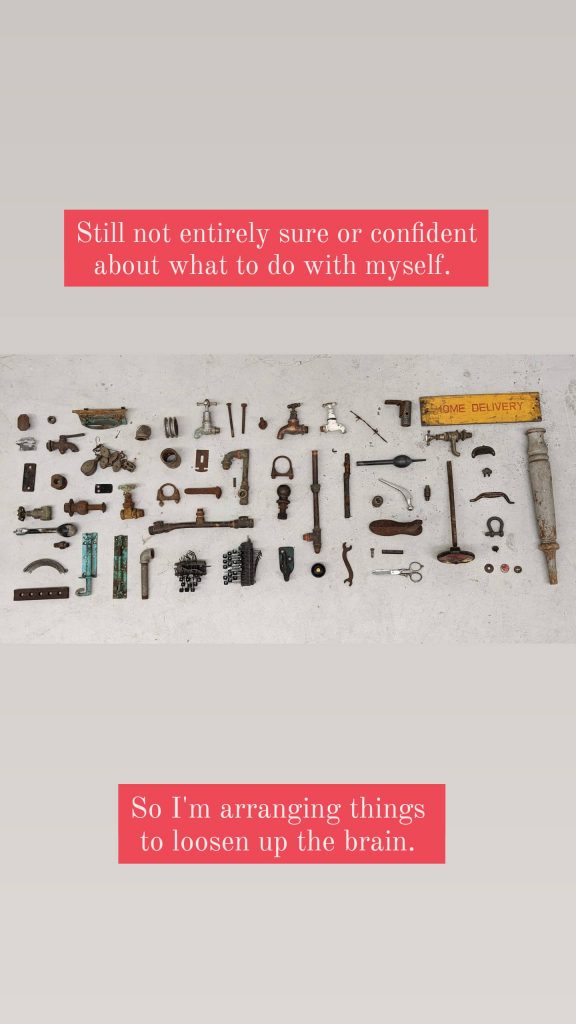

Time in the studio. Non-bronze experiments.

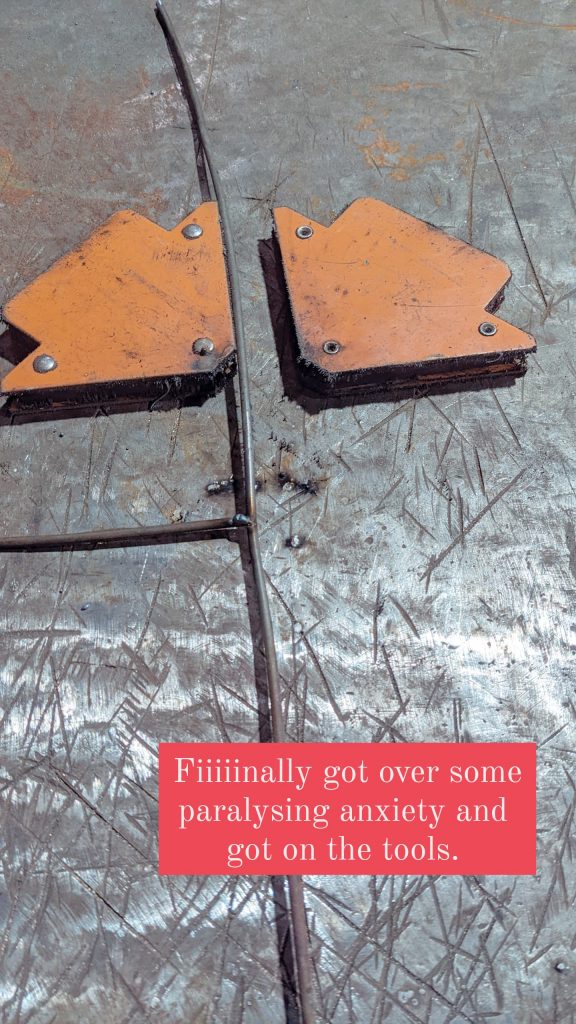

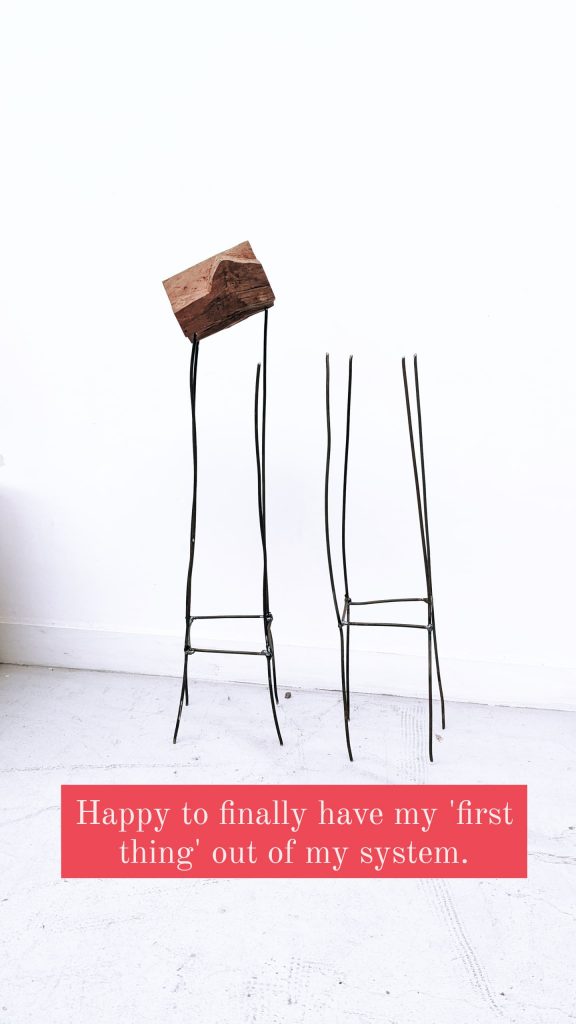

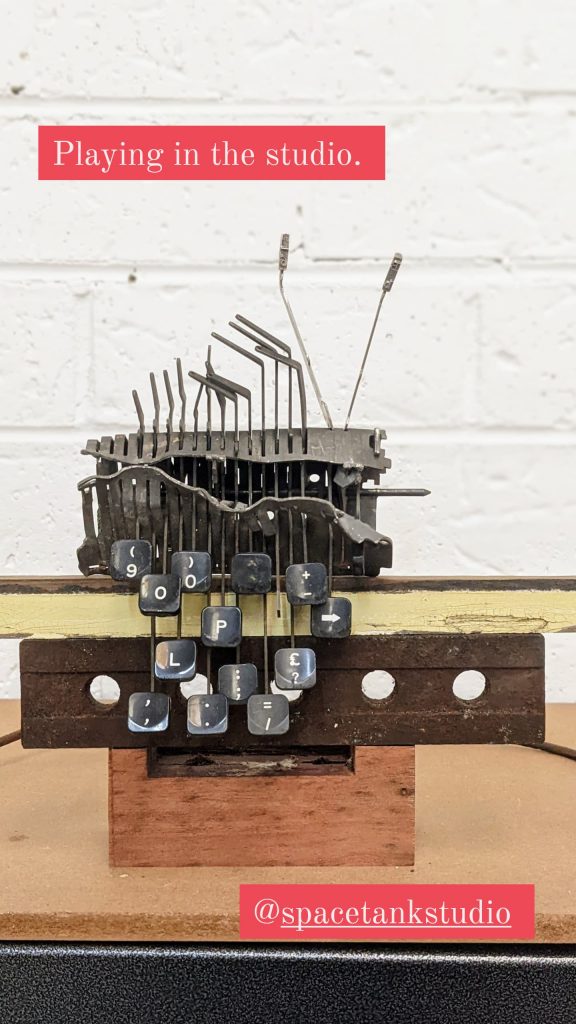

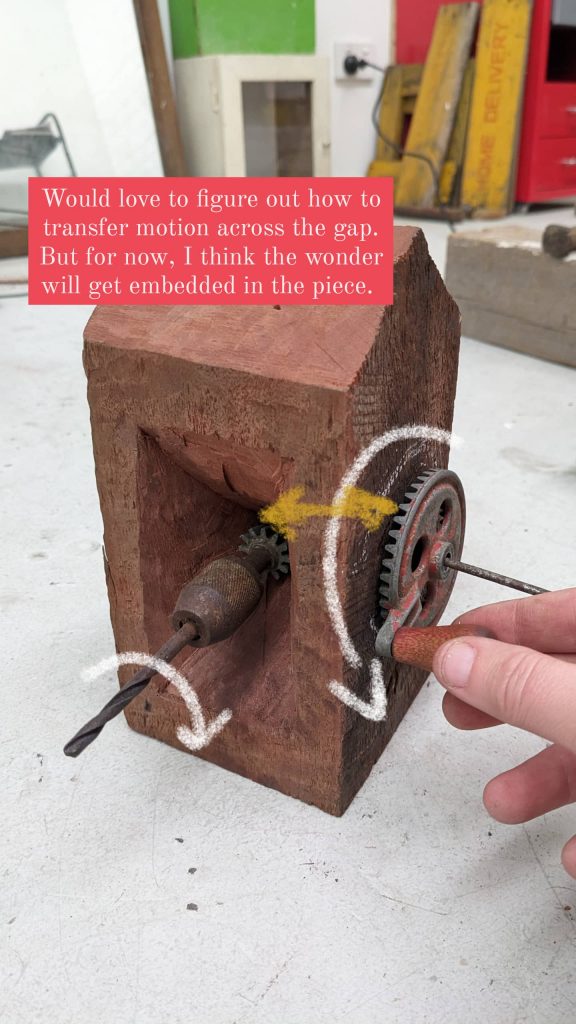

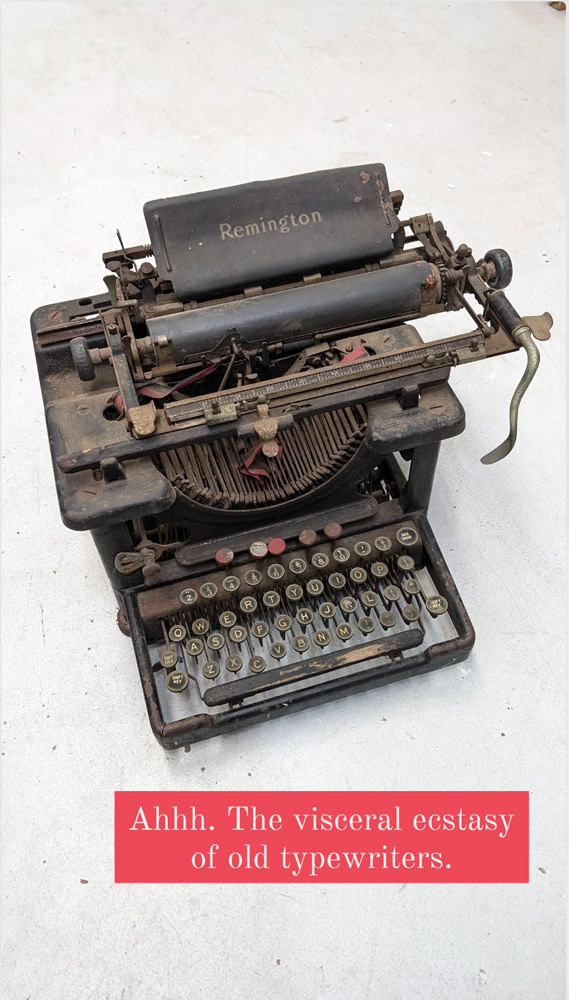

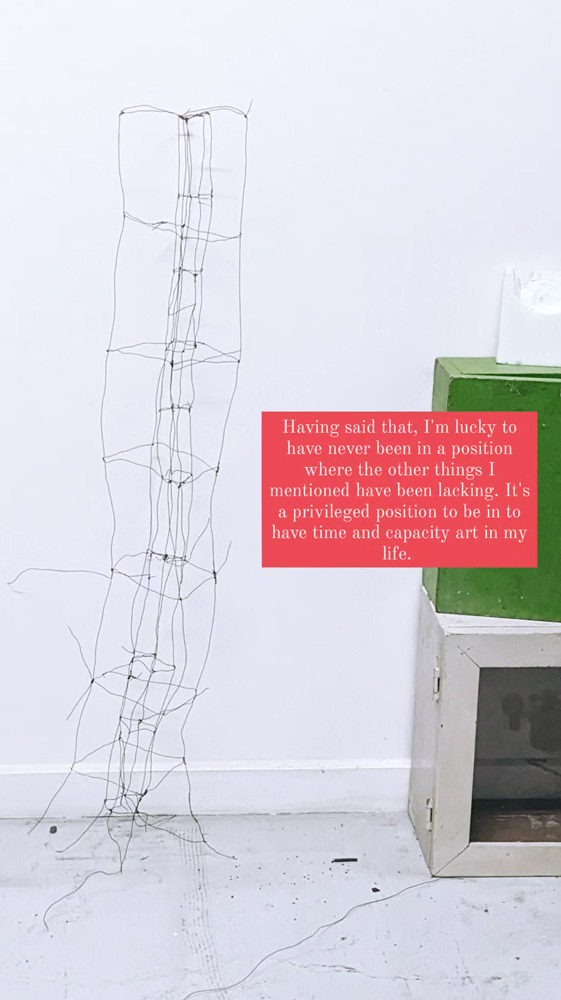

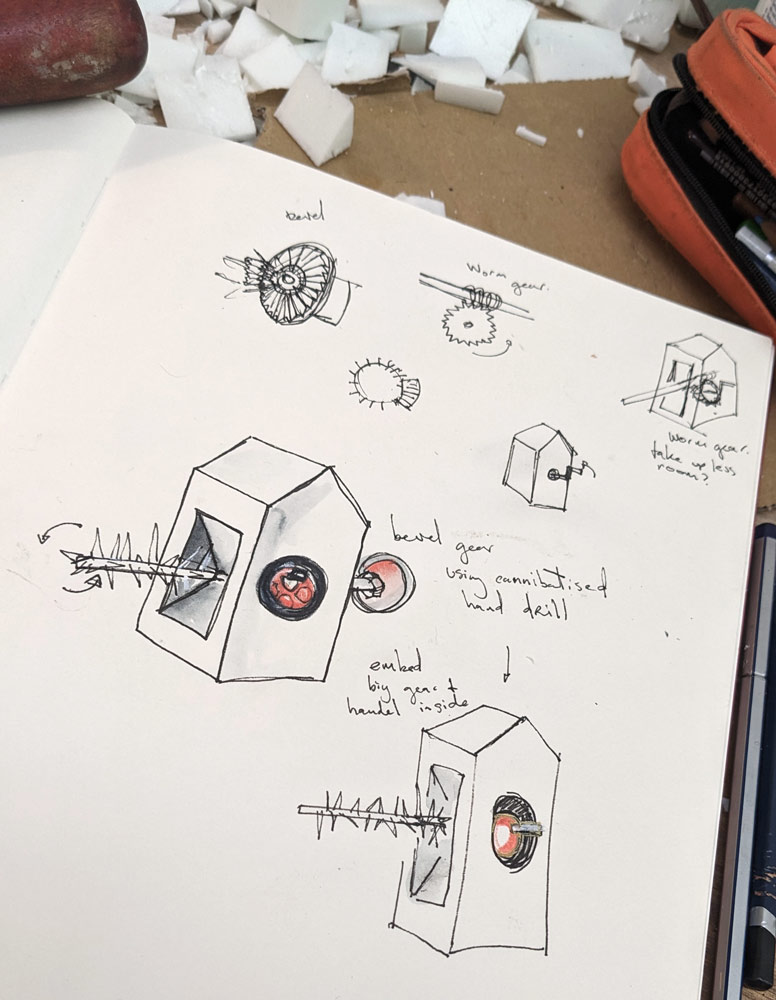

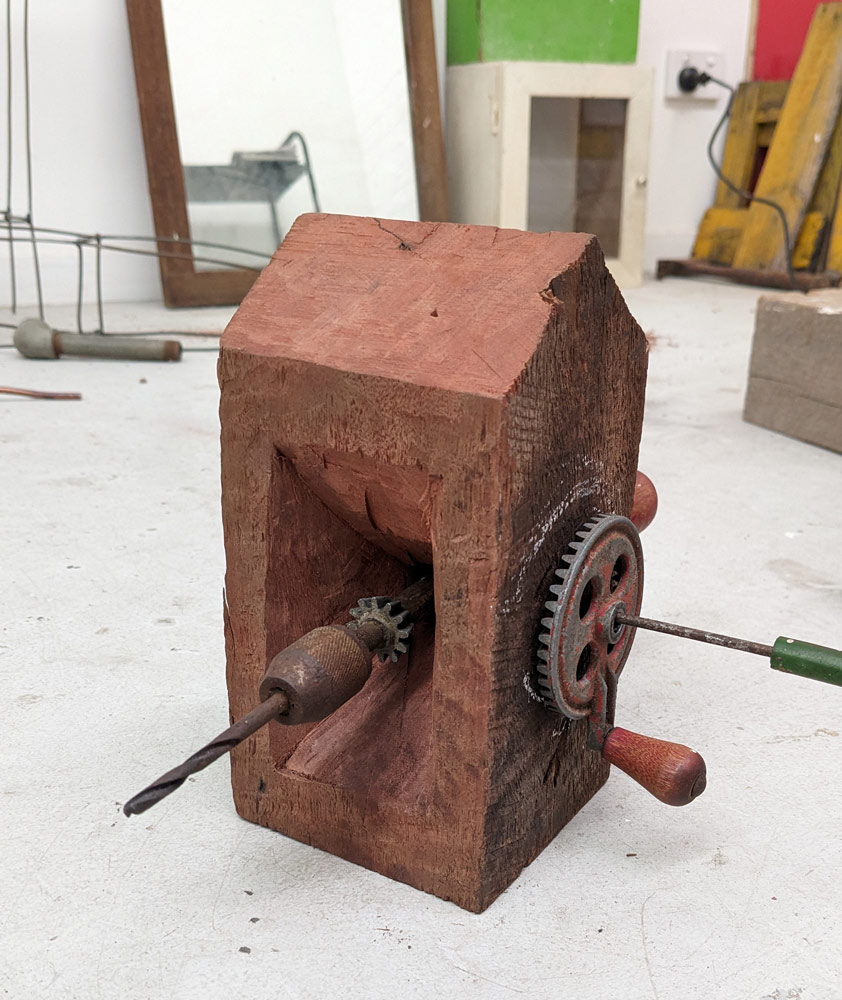

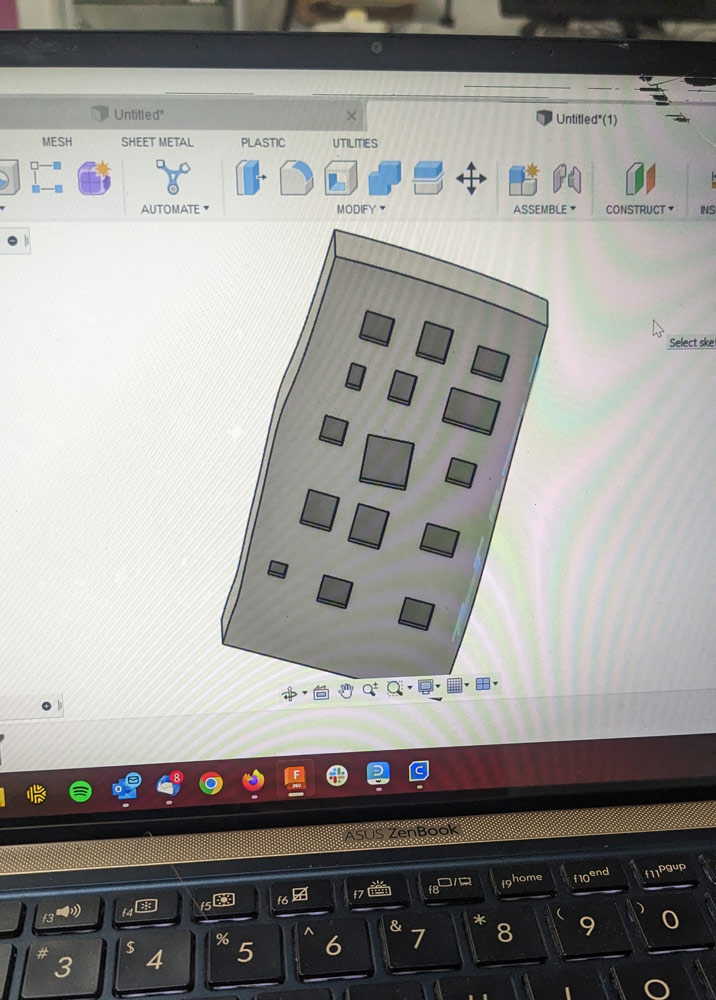

Though bronze casting was my most focussed area of exploration and development during my Creators Fund grant, I also had a chance to play with and think about a plethora of other things. I spent a good amount of time browsing through a stack of Make Magazines, reading various books about sculpture (Robert Klippel being on high rotation), undertaking Domestika courses in woodworking and jewellery design, tinkering with gears and levers while dreaming of large scale red gum automata, learning to weld, learning about 3d printing including how to design in Fusion 360, creating my tallest to date freestanding wire tower, carving and consorting with the fine canine company that Space Tank had to offer.

Time to think expansively, especially in an environment outside one’s home, is worth its weight in gold. There’s also a certain kind of magic in being surrounded by other people who ware also tinkering away on projects, realising their passions, refining their craft.